The Need For Speed...

20P originally had the standard windshield up to the wing,

standard doors and a full Lexan rear enclosure. It worked OK,

but in terms of drag, the MKIII is a badminton birdie on a grand

scale. Picture pushing a large badminton cone through the air,

and visualize how the air would swirl around the back side, and

that's kinda' how it is. Also, the radiator mounted at the rear

of the cage was originally inefficient because of the disturbed

airflow caused by the windshield and doors. One of the first performance

modifications I made to 20P was a shortened windshield. With the

shortened windshield and doors, it cooled the engine very well.

The picture on the left shows it in that configuration, and I

flew it that way from 1996 to 2001. It was great in warm weather...

In spring 2002, I changed the shape of the windshield,

added an air scoop along the top of the windshield, enclosed the

rear upper fuselage in an effort to be able to have an efficient

radiator and an enclosed cockpit for winter flying. It did not

work very well, caused disturbed airflow on the tail, so there

are no pictures. Some things are better forgotten...

During the spring of '03 I changed it to the configuration

on the upper right, which was a great improvement. The upper rear

cabin top was made of 1/16" Lexan, which could be opened

along the side for summer ventilation, or closed in the winter.

However the shape was not optimum, and the radiator cooling was

marginal on hot days.

During the spring of '08 I changed it to the way

it looks in the two pictures below, and I kept those doors until

spring of 2014.

20P is now a true parasol wing configuration, there

is a 5" gap between the bottom of the wing and the top of

the windshield/turtledeck. Flight characteristics are very good,

the fuselage is more streamlined and cuts the air more efficiently.

Airspeeds fully enclosed are 50mph at 4500 rpm, 60mph at 5000

rpm, 70mph at 5600 rpm, 80mph at 6000 rpm, and around 84 mph at

6500 rpm, and that's flat out. The rate of climb is improved with

the wing completely exposed, solo with full fuel on a summer day

typically gives a climb rate of around 800-900'/minute@6250 rpm.

In the winter, it gets even better, a climb rate of 1000-1200'/min

@ 6250 rpm. These airspeed and climb numbers are an improvement

over what the airplane would do new and in stock configuration,

which shows just how adaptable to tweaking the MKIII really is.

The biggest hurdle the MKIII has to overcome in

order to be efficient at cutting through the air is it's width,

normally made even worse by the standard doors. Replacing the

standard doors with flat doors reduces the width by a good margin.

Something very important which is easily overlooked is the improvement

of airflow into the prop. Stock, the top half of the prop is typically

in clean air, and the bottom half of the prop is partially blanked,

or in trashy air, caused primarily by the windshield which goes

to the wing leading edge, and to a lesser extent, the bulging

doors. This turbulence causes the top half of the prop to be more

efficient than the bottom half, and requires more nose up trim

to counteract the stronger push, or thrust vector above the airplane.

By getting more air into the lower half of the prop, you increase

total thrust, & you balance out the thrust vector much better,

which reduces the amount of up elevator trim needed, which reduces

drag.

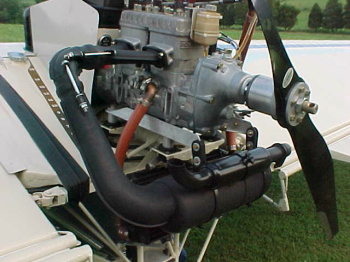

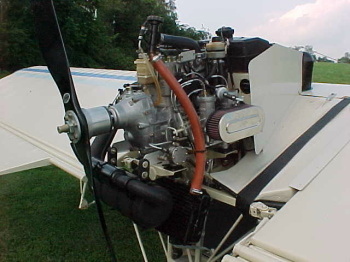

Something that I was not real happy with was the

location of the muffler. Being hung out in the air alongside the

engine surely wasn't helping air flow, so I moved it. I replaced

the stock curlicue expansion pipe with the Quicksilver based 90

degree pipe, and hung the muffler behind the radiator, behind

and below the engine, where it lies in air flowing between the

wing and the cabin top. It is supported by two 1.5" x 1/8"

aluminum angles that run under the stock motor mount plate, and

stick out toward the rear.

This also has the advantage of keeping the muffler

in the same plane of vibration as the engine, instead of cantilevered

out to the side, now it shakes a whole lot less, which so far

has kept it from splitting. I have had 2 of the curlicue mufflers

split along the seam around the curve, and a couple friends have

also had that happen. This muffler position will only fit if you

have the Ivo prop hub extension or similar. Sorry, I don't know

if the wings will still fold or not, because I don't fold mine,

I take 'em off. The fuel pump is mounted on one of the muffler

mounting angles, a convenient place. All fuel line is 1/4"

aluminum fuel line tubing, joined with standard automobile rubber

fuel hose.

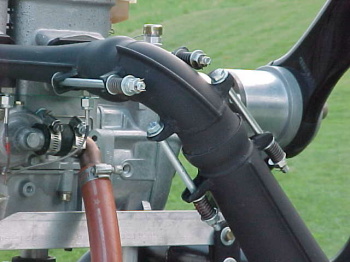

The muffler is hung with rubber muffler hangers

from Advance Auto Parts. ( Why not? ) I got tired of the Rotax

exhaust springs breaking and fabricated some compression bolts

to hold the various pieces of the exhaust in place. It uses 5/16"

bolts compressing springs that are trapped by the bolts. This

has proven to be a very reliable arrangement. The bolts gradually

wear where they go through the brackets and can be replaced during

annual condition inspection. The ballistic parachute & engine

fairing in front of the engine is non-structural and is made from

.024 2024T3 which attaches to the fuel tank via piano hinges epoxied

to the top of the fuel tank. It supports the oil injection tank,

which came off a Murray lawn mower, holds 1.5 gallons, and was

free.

The muffler is hung with rubber muffler hangers

from Advance Auto Parts. ( Why not? ) I got tired of the Rotax

exhaust springs breaking and fabricated some compression bolts

to hold the various pieces of the exhaust in place. It uses 5/16"

bolts compressing springs that are trapped by the bolts. This

has proven to be a very reliable arrangement. The bolts gradually

wear where they go through the brackets and can be replaced during

annual condition inspection. The ballistic parachute & engine

fairing in front of the engine is non-structural and is made from

.024 2024T3 which attaches to the fuel tank via piano hinges epoxied

to the top of the fuel tank. It supports the oil injection tank,

which came off a Murray lawn mower, holds 1.5 gallons, and was

free.

The fairing also houses a Hobbs meter for the engine.

The Hobbs turns on when the airspeed gets up high enough to push

the little aluminum tab and close the microswitch. The strobe

is held on by one of the straps which holds on the oil tank, keeps

it from vibrating. The oil tank uses a float bobber to keep track

of the oil level.

The fairing also houses a Hobbs meter for the engine.

The Hobbs turns on when the airspeed gets up high enough to push

the little aluminum tab and close the microswitch. The strobe

is held on by one of the straps which holds on the oil tank, keeps

it from vibrating. The oil tank uses a float bobber to keep track

of the oil level.

Those nice plastic fairings that Kolb uses to streamline

the lift struts also work great on the landing gear. You may not

think that would make much difference, but the first time I flew

after installing them, the airplane wanted to fly nose high, and

required noticable retrimming. That means some drag was eliminated.

In 2013 I finally installed the tapered steel gear legs that I

purchased years ago, so the fairings and wheel fenders no longer

fit, but it sure makes the landings a lot smoother.

Those nice plastic fairings that Kolb uses to streamline

the lift struts also work great on the landing gear. You may not

think that would make much difference, but the first time I flew

after installing them, the airplane wanted to fly nose high, and

required noticable retrimming. That means some drag was eliminated.

In 2013 I finally installed the tapered steel gear legs that I

purchased years ago, so the fairings and wheel fenders no longer

fit, but it sure makes the landings a lot smoother.