15 Gallon Fuel Tanks

The MKIII has very little room behind/below

the seats for Stuff, and us Old Poops need to take Stuff with

us when we go aviating. Also, the stock 10 gallons of gas was

not much range with two people. 15 gallons is better.

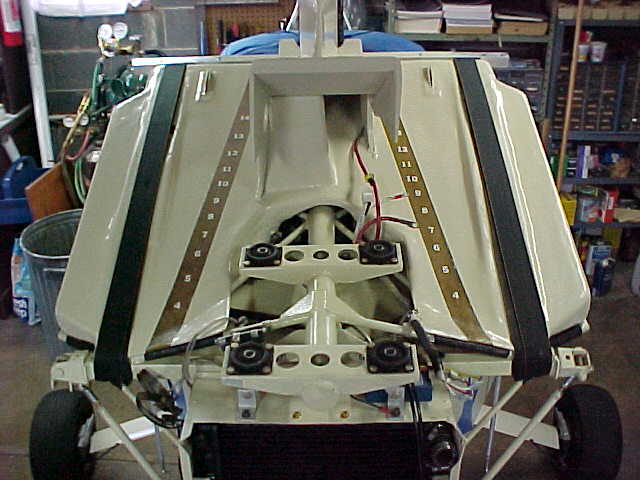

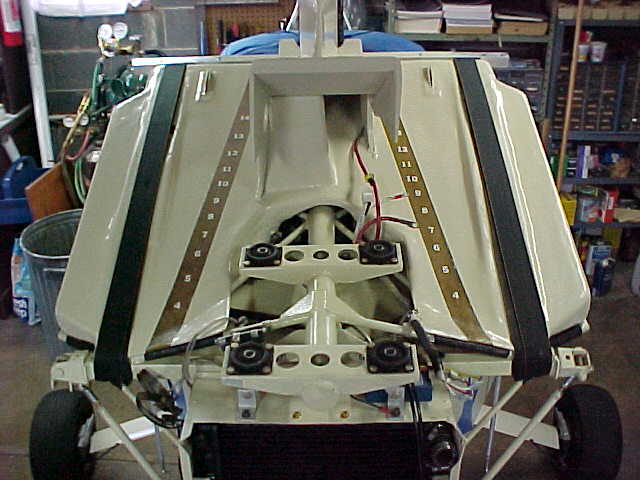

The gap seal area is now fuel tank,

and holds 13 gallons. It weighs about 15 pounds empty and is 5

to 9 plys thick, depending on the stress areas. It rests on all

the upper fuselage tubes, each of which is covered with a rubber

radiator or heater hose, split and glued to the tubes. It was

not very difficult to make, but very tedious & messy.

I do not remember what brand of epoxy

I made it from, but it was/is not ethanol safe. Gasohol in an

epoxy based fuel tank will cause you much grief! Guess how I know

this?

The tank is held in place with seat

belt webbing which also secures an aluminum angle that the front

gapseal is attached to. Unpainted areas are marked for fuel level.

The front part of the tank in these pictures had a built up section

that elevated the fuel filler to a higher position. Around this

elevated section was a balsa wood streamline that blended the

airflow off the parachute launcher and then smoothly redirected

the airflow up, over, and around the engine. That has since been

redesigned, but I didn't take any pictures while I did that part.

You'll see the current version on another page.

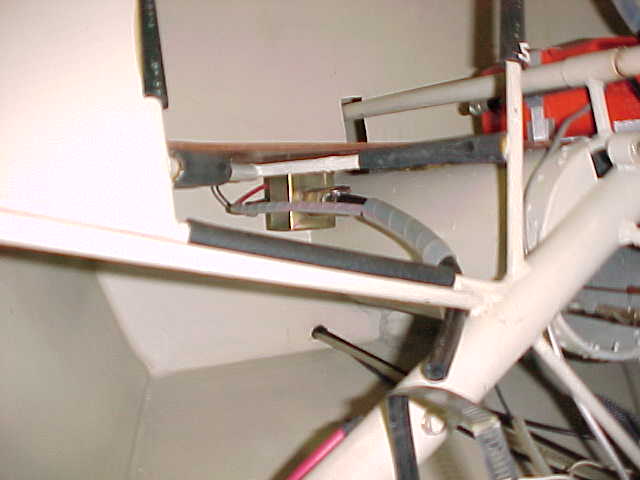

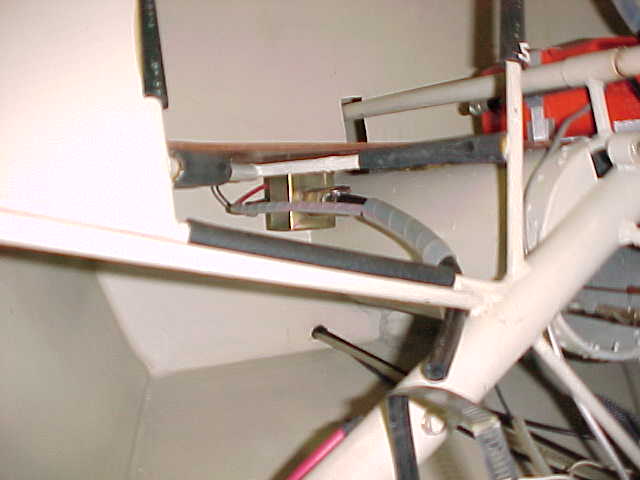

The tank was made by forming it in

place around the upper fuselage tubes. The tubes were wrapped

with two thicknesses of heater hose to allow for the thickness

of the tank to increase as extra plys were added to the outside

as it was built up. The shape of the lower half of the tank was

formed in place out of aluminum flashing from Lowe's, which was

covered in duct tape, and braced with wood. Then the glass cloth

and epoxy was laid up inside the aluminum onto the duct tape covered

areas. Epoxy will not stick to duct tape. These pictures show

the mold just before the layup began.

The glass plys were laid up inside

and allowed to cure, then the mold was removed and stripped off.

The top edge of the tank sides were cut to just below airfoil

shape and a 1"x1"x1/16" aluminum angle was attached

to the upper inside edge to provide an attach flange for the upper

surface of the tank. The easiest way to securely bond a metal

angle or similar item to a fiberglass surface is to drill and

cleco it, and then when you get ready to glass it, mix up a batch

of flox and epoxy to make a thick slurry, spread it on both surfaces

and then secure everything with pop rivits. The tank top is flat

and was made by covering a flat table with duct tape, laying the

cloth on it, wetting it out with epoxy, and letting it cure. Then

just pull it off and trim it to size.

After the fuel pickups, vent lines

and transfer lines were installed, (the lower surface of the tank

divides into four sections to fit around the fuselage tubes, and

you need to have a way for the front sections to drain into the

back ones) the tank top was drilled, clecoed, slurried and rivited

into place. Then the gas filler neck was glassed on and it was

done. Then the whole tank got two more layers of glass, with extra

layers in high stress areas. Due to the complexity of the plumbing,

such as the fuel transfer lines between the front and rear sections

of the tank, vent lines, and feeder lines, removing the tank from

the airplane is not something that is undertaken lightly, and

be sure to use real fuel line (not the plastic ultralight junk)

for those hard to get to transfer lines...

The main tank feeds a 2.5 gallon hopper

tank located behind the passenger seat. That area was modified

with the addition of an extra brace tube welded in to give the

tank something more to rest on, and all tubes were covered with

split 3/8" fuel hose, glued in place. At left is the area

modified and ready. Center, is the cargo bay floorboard with the

Facet electric fuel pump installed. At right is the tank as seen

from the rear side. The hopper tank is fed from the main tank

and vented to it, making a closed system. The fuel pickup is 2.5"

from the tank bottom, and the sump drain is at the bottom. It

takes more than 1/2 pint of water in the tank before it gets to

the fuel pickup.

The ELT is visible in the picture to the left, attached

to the cargo bay floor behind the pilot's seat. The center picture

shows the tank in place, the right picture shows it strapped in

and plumbed. There is a clear sight tubing running along the left

front edge of the tank for a fuel gauge. Replace this every year,

clear fuel tubing is most unreliable and subject to failure.

The cargo area is 13" high, as wide as the

fuselage, and 15" front to back. The floor of the cargo area

is 3/16" plywood. Between what you can fit in the cargo area,

plus underneath it, there is lots of room for "Stuff",

and it is all right on the center of gravity.

The ELT is visible in the picture to the left, attached

to the cargo bay floor behind the pilot's seat. The center picture

shows the tank in place, the right picture shows it strapped in

and plumbed. There is a clear sight tubing running along the left

front edge of the tank for a fuel gauge. Replace this every year,

clear fuel tubing is most unreliable and subject to failure.

The cargo area is 13" high, as wide as the

fuselage, and 15" front to back. The floor of the cargo area

is 3/16" plywood. Between what you can fit in the cargo area,

plus underneath it, there is lots of room for "Stuff",

and it is all right on the center of gravity.